Industrial Machinery in the UK: Types, Safety, and Emerging Trends

Outline

– Context: Why industrial machinery matters to the UK economy and everyday supply chains.

– Scope: Types of machines in factories, process plants, and logistics hubs, and how they fit together.

– Operations: How equipment improves quality, throughput, and flexibility while managing costs and risks.

– Assurance: Safety, compliance, and governance frameworks that underpin responsible use.

– Direction: Near-term and long-range developments shaping investment and maintenance strategies.

Introduction

Industrial machinery is the quiet engine behind the UK economy’s resilience, enabling everything from precision metal parts and packaged foods to pharmaceuticals and low-carbon infrastructure. With manufacturing’s share of national output hovering around a tenth and supporting millions of jobs across regions, equipment choices ripple through productivity, exports, and wages. In an era of tight margins and changing trade patterns, the right machines safeguard quality and continuity while lowering energy and material waste. This article translates big, sometimes abstract topics into practical insights for decision‑makers who need to modernize lines, keep people safe, and future‑proof assets without overspend.

An Overview of Industrial Machinery Used in the UK

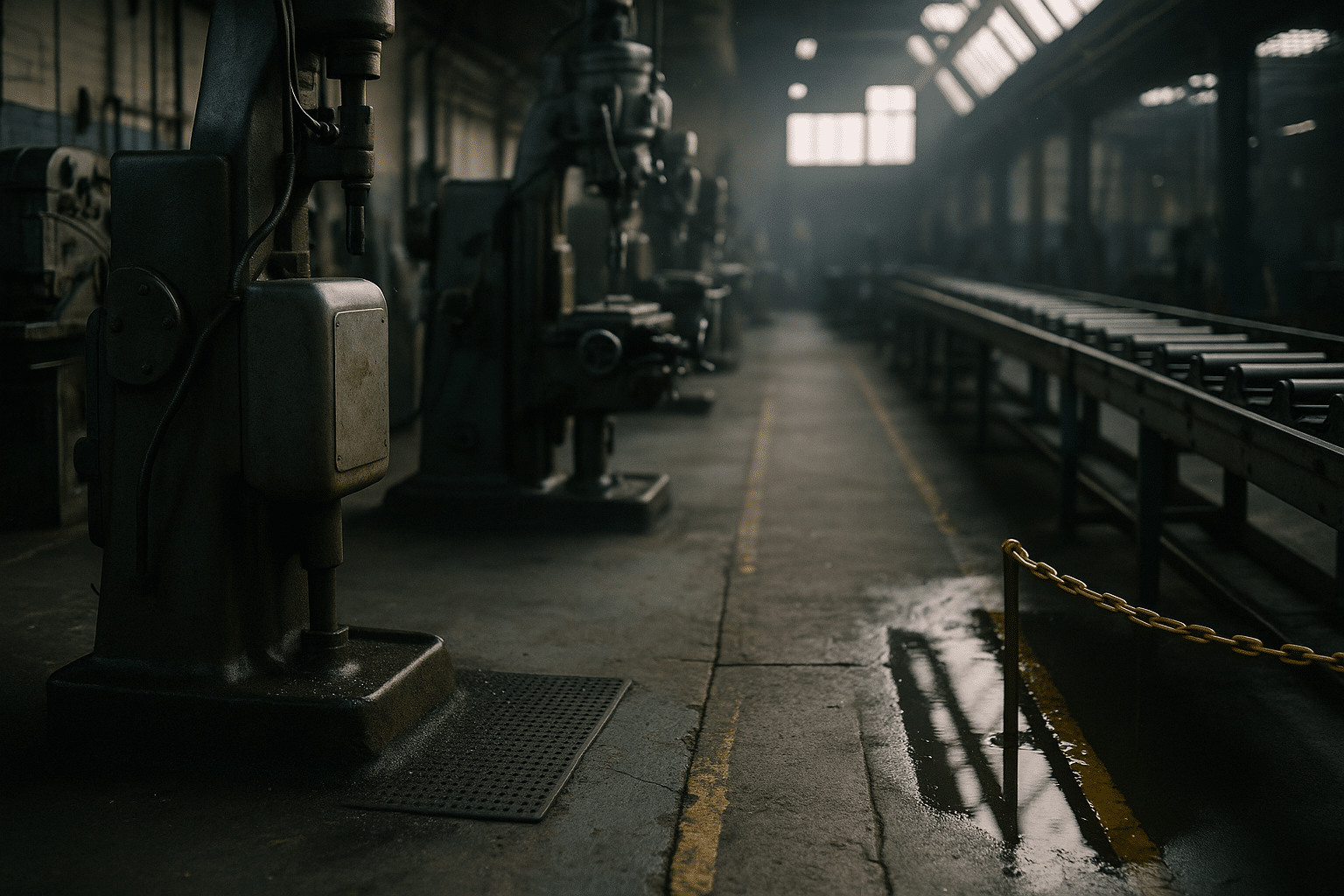

The landscape of industrial machinery in the UK stretches from compact workshop tools to large continuous-process systems, forming a backbone for sectors such as precision engineering, food and drink, life sciences, construction materials, energy technologies, and logistics. At one end, machine tools cut, form, and finish components to tight tolerances; at the other, conveyors, pumps, and mixers keep bulk operations running around the clock. In between sit inspection systems, packaging lines, ovens, chillers, compressors, and controls that coordinate flow, quality, and safety. Together, they convert materials into products through repeatable and traceable steps.

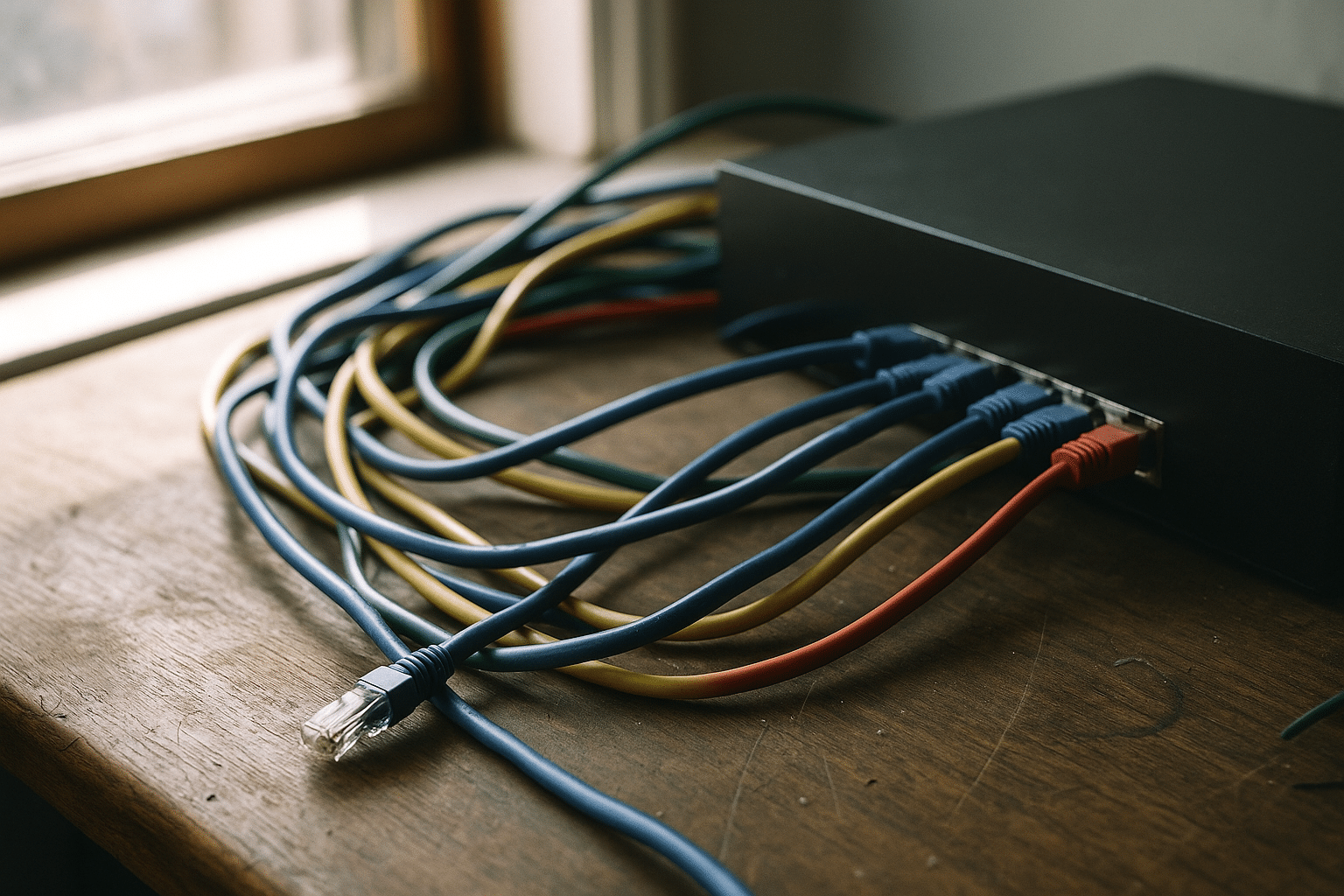

Capacity and reliability are central. Firms balance capital expenditure with life‑cycle costs, weighing power consumption, maintenance intervals, spares availability, and the ease of changeovers. The picture is geographically varied: heavy fabrication often clusters near transport links; high‑value assembly gravitates to skills hubs; food processing follows agricultural supply; and distribution centers align with major road corridors. Many facilities combine legacy assets with newer cells, integrating them via sensors and gateways to monitor throughput and condition without wholesale replacement.

Typical roles across facilities include:

– Forming and shaping: cutting, bending, pressing, and additive techniques for prototypes and short runs.

– Thermal and chemical processing: heat treatment, curing, drying, pasteurizing, and blending.

– Handling and movement: pallet trucks, automated storage, conveyors, and lifts that reduce manual strain.

– Quality and packaging: vision checks, weight control, sealing, and labelling interfaces for downstream logistics.

– Utilities and services: compressed air, steam, chilled water, and power distribution that keep lines stable.

Viewed as a system, the UK’s machinery base underpins export competitiveness and supply reliability. While global pressures affect lead times for parts and materials, diversified equipment portfolios and methodical maintenance help firms ride out fluctuations, protect delivery schedules, and serve customers with consistency.

Key Types of Industrial Machines Across UK Industries

The UK’s industrial footprint relies on a set of machine categories that recur across sectors, each fulfilling specific tasks yet increasingly connected through shared data and controls. Discrete manufacturing facilities often rely on machining centers, presses, laser cutters, and surface finishing equipment to create and refine components. Process industries lean on pumps, valves, mixers, reactors, and filtration units to transform inputs continuously under tight temperature, flow, and pressure limits. Warehousing and packaging areas integrate conveyors, palletizers, case erectors, and weighers to synchronize material flow and order fulfillment.

A practical way to think about types is by function rather than industry label:

– Material transformation: cutting, forming, casting, molding, additive processes, heat treatment, and coating.

– Motion and handling: hoists, cranes, automated storage and retrieval, guided vehicles, and sortation.

– Utilities and HVAC: boilers, chillers, cooling towers, air compressors, and vacuum systems.

– Inspection and testing: dimensional metrology, non‑destructive testing, and in‑line vision.

– Control and automation: programmable controllers, drive systems, sensors, and safety relays.

Specialized niches exist as well. Food producers deploy hygienic design equipment with quick‑clean features and stainless surfaces; pharmaceuticals require validated systems with batch records and traceability; fabrication shops value flexible setups for short runs; and construction product plants prioritize ruggedness and easy maintenance. In many facilities, multipurpose machines with rapid tool or recipe changes allow operators to switch from one product to another within minutes, conserving floor space and smoothing demand peaks without adding shifts.

Selection hinges on more than nameplate capacity. Decision‑makers compare throughput per square metre, energy use per unit, changeover time, scrap rates, and the availability of local service. Where space is tight, compact footprints and vertical layouts matter. Where skills are scarce, intuitive interfaces, standardized spares, and clear maintenance documentation reduce downtime. The result is a mixed estate that blends high‑precision machines where quality is critical with robust workhorses where volume and uptime dominate—an approach that creates resiliency without unnecessary complexity.

How Industrial Machinery Supports Manufacturing and Production

Industrial machinery enables manufacturers to convert plans into repeatable output while balancing speed, flexibility, and cost. At the line level, equipment shortens cycle times, stabilizes quality, and captures data that teams use to improve. Automated changeovers reduce switches from hours to minutes; accurate drives and fixtures cut rework; and in‑line checks catch defects early before they multiply downstream. Across the day, consistent feed rates and synchronized stations create smoother flow, reducing pile‑ups that would otherwise waste time and energy.

Performance management links closely to equipment capability. Many teams track availability, performance, and quality as a simple composite, using it to spot chronic losses. The greatest gains often come from eliminating avoidable stops—such as unplanned micro‑halts—or from standardizing work to cut variability during changeovers and startups. Digital condition monitoring alerts maintenance before a fault escalates, allowing planned interventions during natural breaks. Equally, small ergonomic improvements—better guards, clearer sightlines, simple tool‑less adjustments—encourage operators to keep machines within process windows.

Output is not the only metric. Modern systems help dial down energy per unit and material waste. Examples include variable‑speed drives that match load, heat recovery on ovens or dryers, and recipe controls that fine‑tune mixing or curing to the minimum necessary time and temperature. Over a year, these measures create steady savings that compound, freeing cash for targeted upgrades. For make‑to‑order businesses, flexible fixtures and modular cells shorten lead times and enable small batches without excess inventory, which improves cash flow and responsiveness to customers.

From a resilience perspective, diversified machinery and cross‑trained teams protect operations from single points of failure. Spare capacity at critical steps, interchangeable tooling, and documented standard methods let plants absorb supplier delays or demand spikes without compromising safety or quality. In short, machinery supports manufacturing and production by anchoring process discipline, enabling continuous improvement, and creating options—so that when conditions change, the factory can adapt with minimal disruption and measured risk.

Regulatory and Safety Considerations for Industrial Machines in the UK

Safety and compliance are foundational to responsible operations, shaping machine design, integration, and day‑to‑day use. In the UK, duty holders assess risks, implement controls, verify conformity with applicable machinery requirements, and ensure competence through training and supervision. Key obligations include guarding hazardous motions, preventing unexpected start‑up, managing energy isolation, and providing clear information for use. Conformity assessment and appropriate marking signal that machinery meets essential health and safety requirements, while workplace regulations govern selection, installation, inspection, and maintenance once equipment is in service.

Effective programs treat safety as a lifecycle:

– Design and procurement: specify performance levels for safety functions, require technical files, and check compatibility with existing systems.

– Commissioning: validate safety‑related parts, verify interlocks, test emergency stops, and document results.

– Operation: train operators on normal and abnormal conditions, keep instructions accessible, and maintain housekeeping.

– Maintenance: apply lockout procedures, verify zero energy states, and return equipment to service with functional checks.

– Change management: reassess risks after modifications, software updates, or recipe changes.

Good practice goes beyond hardware. Visual standards for guarding, consistent color coding for isolation points, and clear escalation paths for defects help teams act quickly. For hazardous atmospheres or high‑energy systems, additional requirements apply, including zoning and equipment selection that prevents ignition or uncontrolled release. Records matter: periodic thorough examinations, calibration logs for sensors, and documented corrective actions provide evidence that controls are working and that management reviews risks regularly.

Compliance also intersects with sustainability and wellbeing. Lower noise levels, better ventilation, and dust control protect long‑term health; efficient drives and compressed‑air management reduce emissions and costs; and ergonomic design lowers strain injuries. When regulatory and safety considerations for industrial machines in the UK are addressed in this integrated way, organizations gain more than a certificate—they build reliability, credibility, and a stronger culture where people can solve problems without fear.

Trends and Technological Developments in UK Industrial Machinery

The machinery estate is evolving as sensors, connectivity, and software become standard features rather than add‑ons. Data from drives, motors, and controllers now feeds dashboards that highlight bottlenecks and predict failures, allowing teams to plan short, surgical stops instead of long, disruptive breakdowns. Edge analytics limits bandwidth while keeping critical insights close to the process; secure remote access reduces travel time for diagnostics; and digital twins help test changes before they touch physical lines. The result is a calmer, more predictable production rhythm.

Electrification and efficiency are advancing quickly. Variable‑speed systems match energy to load on pumps and fans, often trimming consumption significantly. Heat recovery and better insulation reduce losses in ovens and dryers. In compressed‑air networks, leak detection, proper pressure settings, and smart controls collectively curb waste that can erode margins. Meanwhile, modular equipment designs let factories extend capacity by adding standardized stations, easing commissioning and shortening payback. For small and mid‑sized sites, retrofit kits bring older machines into this connected, efficient world without full replacement.

Human‑machine collaboration is another frontier. Ergonomic fixtures and assistive devices reduce lift and twist, while guarded collaborative robots handle repetitive or hazardous tasks within well‑defined envelopes. In quality, machine vision and acoustic monitoring detect subtle defects that escape the naked eye, supporting consistent outcomes without slowing the line. Materials handling continues to mature with more flexible navigation for vehicles and better slotting strategies in storage, cutting travel time and errors.

Finally, sustainability is shaping investment criteria. Buyers weigh embodied carbon, serviceability, and end‑of‑life options alongside speed and accuracy. Remanufacturing and component reuse extend the life of heavy assets; standardized spares and open interfaces reduce lock‑in; and transparent data supports reporting obligations. These trends and technological developments in UK industrial machinery point toward equipment that is smarter, cleaner, and easier to adapt—helping organizations invest confidently despite uncertainty in demand, labor markets, and energy prices.

Conclusion

For operations leaders, engineers, and procurement teams, the path forward is clear: take a system view, align equipment with real constraints, and build safety and data into every decision. Start by benchmarking current performance, then target quick wins in changeovers, energy, and maintenance before funding larger upgrades. Prioritize compliant, well‑documented machines with credible lifecycle support, and use pilots to de‑risk new technologies. By steadily modernizing, you can strengthen uptime, protect people, and unlock capacity—without betting the factory on a single leap.